The Challenge

Client: Jan Hovens

Jan Hovens, a woodworker, encountered a problem with his briquette press machine. A device that turns wood shavings/dust and compresses it into briquettes to fuel fires. The issue was that the briquettes easily broke down as the wood did not stick properly together.

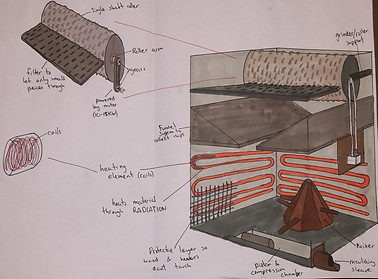

Ideation

The team's main focus was to shred and heat the wood waste before it enters the compression chamber. Therefore, the shavings would warm up and be of consistent size, hence making it stick more efficiently together and forming a more durable briquette.

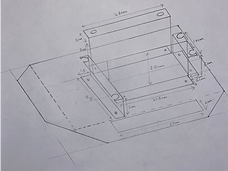

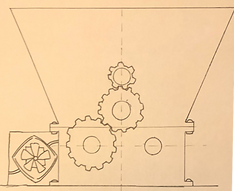

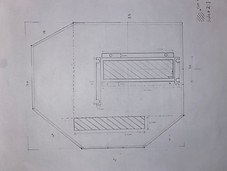

Final design

This redesign adds a lid to the briquette press which holds the shredder. It also carries a funnel on top that feeds the wood shavings into the shredder before it falls towards the heating chamber and then into the compression chamber at the bottom. The funnel contains two spinning mixers that prevent the irrregular-sized wood shavings from cloging up before being shredded.